Recommended news

- Is the red brick packer the bigger the package, the better2022-03-08

- What characteristics should the special plastic steel belt packing belt for brick factory have2022-03-08

- Yude code blank machine is more popular than traditional code brick2022-03-08

- How to prolong the service life of brick electric packer2022-03-08

- Characteristics of intelligent robot blank coder2022-03-08

How to choose automatic blank coder and robot

Robots are classified according to working load. At present, 250kg, 300kg, 450kg, 500kg, 700kg and 800kg are commonly used in China. The working cycle of some robots is light, and the working cycle of some robots is allowed to be fast. Generally speaking, the working cycle of 250kg and 300kg robots is 5 times per minute, and the working cycle of 450kg and 500kg robots is 4 times per minute. Due to the influence of working load, only one set of fixture can be used to clamp up to 48 KPI bricks, that is to say, the output of the robot is 192 pieces / min, and its annual output is basically about 80 million pieces (converted standard bricks). If higher output is required, the number of robots and corresponding supporting equipment can only be increased.

After the billet is clamped by the fixture, the bridge pulley moves on the track to transport the billet to the kiln car. Therefore, there is no requirement for the width of the kiln car. No matter what kind of kiln car, there are matching billet coding machines in China from 2.5 ~ 9.2m kiln car. Moreover, if the process design is reasonable, one billet coding machine can code the billet corresponding to multiple kiln cars.

The robot works by the rotation of its own rotating arm. At present, the arm spread of the robot used in China is no more than 3.2m, which requires the width of the kiln car. The width of kiln car is less than 5.8m, and one robot can cover the whole kiln car surface; If the width of kiln car is greater than 5.8m, two robots must be used to fill the kiln car surface.

wechat number:

wechat number:

contact

contact

wechat

wechat

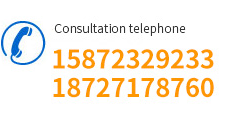

Telephone

Telephone