Recommended news

- Is the red brick packer the bigger the package, the better2022-03-08

- What characteristics should the special plastic steel belt packing belt for brick factory have2022-03-08

- Yude code blank machine is more popular than traditional code brick2022-03-08

- How to prolong the service life of brick electric packer2022-03-08

- Characteristics of intelligent robot blank coder2022-03-08

Development trend of packer in brick factory and selection of packing mode

As we all know, the brick and tile industry is a labor-intensive enterprise. In the production process, the labor demand of palletizing, loading and unloading and other processes is large, time-consuming and high cost. It also needs to face the practical problems of difficult recruitment, difficult management, heavy workload and difficult to ensure compliance. The operation of realizing the above process automation is a good choice for entrepreneurs to solve the problems. The realization of brick stacking and packaging improves the corporate image, solves the management cost of workers, improves the obedience of loading and unloading work, imports and shipments with the same quantity and standardization, and reduces the generation of waste products. The construction site can also reach the construction site in a whole package, which is deeply loved by the majority of construction enterprises.

1. Full automatic baling: this method can be fully automatic palletizing and automatic packaging, with high production compliance and reduced labor costs. However, it is necessary to plan in advance when building the plant. The later transformation cost is high, and the equipment cost is high (mostly imported equipment), the maintenance cost is expensive, the packaging consumables must be imported, and the floor area is large. At present, few large enterprises in China have chosen such a way, and the problems they face are also the same. Some enterprises simply abandon bundling, resulting in great losses.

2. Semi automatic baling: this can partially realize the automation of packaging, meet the requirements of one production line, appropriately reduce the labor cost, and the production is subject to the same routine, requiring manual palletizing (8 people are required to palletize as usual), manual inspection equipment, etc. The investment of this method is about 1 million yuan, and most of the center of gravity balers are imported, but the high maintenance cost and limited functional modules are big problems

3. Manual baling: this method is currently selected by many enterprises. It has the advantages of low equipment cost, simple maintenance service, convenient operation and use, and can realize small-scale production in the early stage; And choose a good packer and service enterprises are particularly nervous. At present, there are three ways of manual packaging, including hand-held electric packer, hand-held pneumatic tool and buckle packer.

wechat number:

wechat number:

contact

contact

wechat

wechat

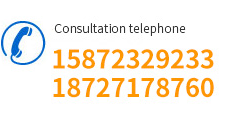

Telephone

Telephone