Recommended news

- Is the red brick packer the bigger the package, the better2022-03-08

- What characteristics should the special plastic steel belt packing belt for brick factory have2022-03-08

- Yude code blank machine is more popular than traditional code brick2022-03-08

- How to prolong the service life of brick electric packer2022-03-08

- Characteristics of intelligent robot blank coder2022-03-08

Construction control measures of hydraulic pollution of billet stacking machine

In brick making enterprises, dust pollution is relatively serious. During pipe laying construction, the construction site of the blank coder shall be clean and shall not be constructed in a dusty and high humidity environment. Where the price of robot blank coder and brick factory blank coder is conditional, the site shall be set aside for the processing and production of pipes to achieve the goal of clean assembly. The hydraulic station, pipes, valves, etc. shall be kept in a relatively clean warehouse.

2. Reasonable selection of pipes and fittings

The hydraulic components and components of the blank stacking machine have been assembled in the factory to the strength of the pipe and the tightness of the interface, and the pipe has been pickled in the factory. The key selection is based on the interface form of the pipeline and valve parts of Jun hydraulic station. The elbow shall be simmered as much as possible, and the pipeline shall be welded with short pipe without reason.

3. Select reasonable construction methods

The laying of hydraulic pipeline of billet stacking machine is a sausage construction project with heavy workload. In the construction process, the following points should be added:

a. After opening the packing box of the hydraulic system of the blank stacking machine, check whether the oil ports of components, components and pipes are wrapped and sealed well, take remedial measures for the oil ports slightly polluted in time, and disassemble and clean the seriously polluted hydraulic components again.

b. The diameter of the steel pipe selected for the hydraulic pipeline of the blank stacking machine is less than 25mm, and the steel pipe connection adopts the ferrule type. This process is mature and reduces the constant pressure caused by welding. According to the ready-made layout, the hydraulic station and the pipeline developed to multiple control points shall be reasonably configured, and the tax ticket or vertical pipe layout shall be adopted as far as possible to facilitate disassembly. Before connecting the pipeline, cut the length of the steel pipe, clean the incision and blow it out with clean compressed air.

c. The joint body and joint shall be cleaned with kerosene before installation. For the joint to be sealed with raw material belt, the raw material belt shall be wound along the thread direction. The raw material belt shall not pass through the end of the thread, otherwise some parts will be cut off by the thread and enter the system during tightening.

d. After the management and construction of the hydraulic system of the blank stacking machine is completed, clean and dry compressed air shall be used to blow it out before putting into operation. It shall be flushed with oil. The flushing system shall form a separate circuit and be disconnected from equipment valves, hydraulic cylinders and other components, and hose short-circuit can be used. After the flushing is qualified, drain the flushing oil, then remove the temporary pipeline and restore the system.

wechat number:

wechat number:

contact

contact

wechat

wechat

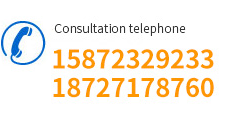

Telephone

Telephone