Recommended news

- Is the red brick packer the bigger the package, the better2022-03-08

- What characteristics should the special plastic steel belt packing belt for brick factory have2022-03-08

- Yude code blank machine is more popular than traditional code brick2022-03-08

- How to prolong the service life of brick electric packer2022-03-08

- Characteristics of intelligent robot blank coder2022-03-08

What kind of blank coder can improve the efficiency of brick factory

First, it needs to be put into operation from the full-automatic blank coder equipment. The models and operation modes in the domestic blank stacking machine industry are almost the same, and operators are generally required: before starting the oil pump, check that each operating handle should be placed in the neutral position, and it is forbidden to start the oil pump with load. The track cylinder shall be in the return position to avoid affecting the rotation of the kiln car. The track cylinder shall be returned in time after each action. The user shall be clear about the working principle of the equipment and be familiar with the position, function and rotation direction of various operation and adjustment handles.

Before start-up, check whether the adjusting handles and hand wheels on the system have been moved by non staff, and whether the positions of electrical switches and travel switches are correct and firm. Wipe the exposed parts first to ensure that they are clean and free of pollution, and then start up, so that the blank coder can automatically swing the cover and transport automatically, Then it can further save the labor of operating the blank coder and reduce the labor intensity, so as to improve the efficiency of the product blank coder. For example, the full-automatic blank coder produced by McGonagall uses this functional feature.

Therefore, the electromechanical integration equipment of full-automatic billet coder has a wide variety and wide application, which can improve the production efficiency of brick factory.

wechat number:

wechat number:

contact

contact

wechat

wechat

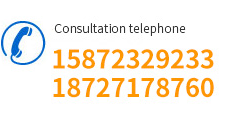

Telephone

Telephone